Textile coating

Textile coating finishing agent, also known as coating glue, is a kind of polymer compound evenly coated on the surface of fabric。

Introduction

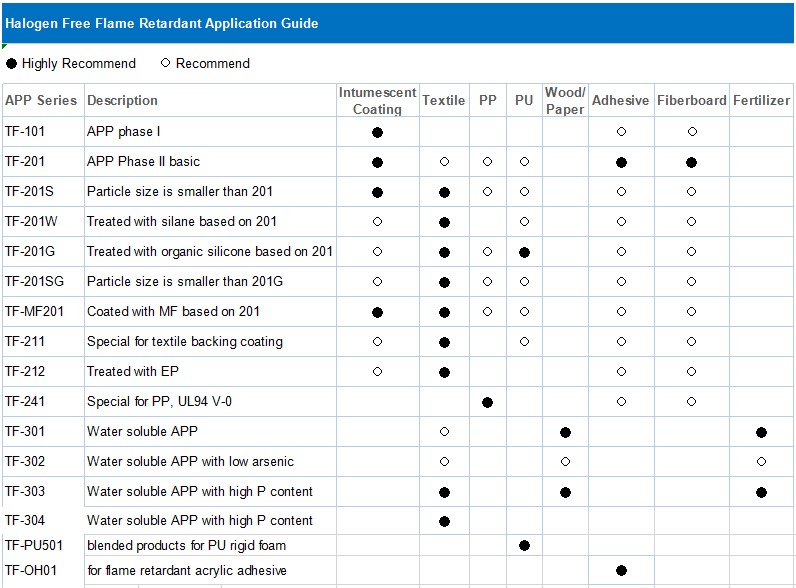

Forming one or more films on the surface of the fabric through adhesion can not only improve the appearance and style of the fabric, but also increase the function of the fabric, so that the fabric is waterproof, resistant to water pressure, breathable and moisture-permeable, flame-resistant, stain-proof, and light-shielding and reflective And other special features. Adding our company''''''''''''''''''''''''''''''''s flame retardant in the coating can achieve excellent flame retardant effect without affecting the feel. Its environmental protection and halogen-free compliance with EU ROHS and REACH directives.

history

As early as more than 2,000 years ago, the ancient Chinese people used coating glue on the surface of fabrics. At that time, they were mostly natural compounds such as lacquer and tung oil, mainly used in the manufacture of waterproof cloth. In modern times, a variety of synthetic polymer coating adhesives with superior performance have appeared. The original product had the defect of only waterproofing but not moisture permeability. The coated fabric had a sweltering feeling and poor comfort when used. In order to improve the breathability and permeability of coating glue, since the 1970s, researchers have developed a series of waterproof and moisture-permeable coating glue for fabrics by modifying the chemical structure of the coating glue and changing the coating processing method. In recent years, functional coating adhesives and composite coating adhesives have also made great progress.

classification

There are many classification methods for coating glue, and the main classifications according to chemical structure are:

1. Polyacrylates (PA);

2. Polyurethanes(PU);

3. Polyvinyl chloride (PVC);

4. Silicone;

5. Synthetic rubbers (e.g. neoprene)。

In addition, there are polytetrafluoroethylene, polyurethane, polyester, polyethylene, polypropylene and proteins. Currently the main applications are polyacrylates and polyurethanes. It is divided into two types: solvent-based and water-based according to the medium used. The solvent-based has the advantages of high water pressure resistance, good film formation, fast drying, and low solid content, but it also has permeability on the fabric. Strong, rough feel, high toxicity, easy to catch fire, need solvent recovery device, and high recovery costs. Compared with the solvent type, the water type is non-toxic, non-flammable, safe, low cost, and does not need to be recycled. It can manufacture thick coating products, which is beneficial to the production of colored coating products. The coating has good hydrophilicity. Drying is slow and sticking to filament fabrics is difficult. According to different coating processes and baking conditions, there are dry coating glue and wet coating glue, low temperature crosslinked coating glue and high temperature crosslinked coating glue. Dry-type and low-temperature cross-linked coating adhesives are the future development trend of coated fabrics because of their simple coating process, low baking temperature, and labor-saving and energy-saving.

method

1. Direct coating: Direct coating is to flatten the fabric to form a uniform plane, and then pass under a stationary scraper. Direct coating is mainly used to process fabrics such as nylon or polyester filament yarns.

2. Transfer coating: Transfer coating is to apply polymer on release paper to form a film, and then press the film on the fabric. In this method, the polymer does not contact the fabric until it forms a true film. Transfer coatings are mainly used on knitted fabrics. Compared with woven fabrics, knitted fabrics are more loosely structured, more prone to elongation, and direct coating techniques cannot be used. Unlike direct coatings, transfer coatings are often used as the surface of a material.

3. Solidified coating: Solidified coating, also known as wet coating, is a method of dissolving polyurethane in a solvent and then removing the solvent under certain conditions to form a solidified body. This material is soft and has a porous structure, which is the basis of imitation leather.